Guidelines to follow for data center grounding and bonding

Data centers have unique types of grounding and bonding, which is different from any other electrical distribution system. For efficient data center rack management, it is essential to consider grounding and bonding seriously. The types of grounding and bonding for a data center are:

- Grounding and bonding of the equipment in the data center

- Grounding of the building distribution system

- Connection of two systems required as per NEC

According to NEC Article 250, we must connect the leading electrical service to a grounding electrode. The electrode must be metallic, and we should make it within five ft. of the waterline entrance into the building. If the water usage is metered, we must install a metallic jumper with the help of listed grounding clamps to remove the water meter without affecting the building grounding. The neutral of the incoming electrical service should be connected to the building grounding system from a single point with a removable connection, so it becomes easy to remove the jumper when needed. Many manufacturers insist on having a separate ground for their equipment that is not connected to the central electrode; different equipment will reduce the system noise and create a hazardous situation for everyone. If there is a voltage difference in the equipment grounding and the building’s grounding, it can cause potential shock for anyone coming in contact with any ground. Henceforth, NEC suggests connecting all the equipment in the building electrically to prevent any such risk.

Basis of grounding:

For utmost safety, NEC suggests the following grounding rules.

- Safety: all the non-current metallic equipment needs to be grounded to ensure they do not conduct any electricity.

- Overcurrent operation: a thoroughly grounded facility quickens the activation of the overcurrent device. Whenever there is a short circuit from the phase conductor to the ground, the breaker or the fuse sees a significant current fluctuation and moves quickly.

- Equipment operation: the ground helps operate the equipment if used as a signal reference ground. If there is any voltage problem on the ground, there might be chances of operational issues.

Special considerations regarding grounding:

Grounding is an essential factor for the proper functioning of data processing equipment, whether it is connected to the building electrical distribution system or connected to a designated power distribution system. An efficient grounding system eliminates the static energy on the ground, but it can also harm sensitive electronic devices. It also prevents any personal injuries that might occur during any voltage differences. Most of the processing system uses standby generators or UPS; they are considered separate systems and need to be grounded separately. The impedance of the building to the ground is highly variable and affects how the building is connected to steel. The first step for grounding electrodes is to ensure that the ground impedance is as low as possible. The ways to maintain low impedance are:

- The grounding electrodes must be at least 110 ft. apart

- A buried ground loop with many ground rods

- Chemically advanced electrodes

- Ufer grounds or any other type of grounding system

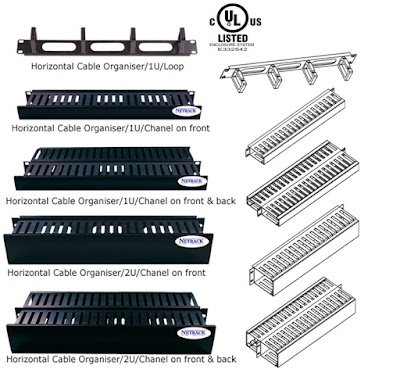

Grounding and Bonding are essential for maintaining a proper data center. It is also necessary to choose the correct Grounding and Bonding Manufacturers for the process. For example, Netrack is a Grounding and Bonding Manufacturer providing excellent solutions to its customers. If you want more information regarding grounding or bonding, you can visit the following site:https://www.netrackindia.com/

Comments

Post a Comment