Netrack server racks cabinet and Fibre distribution units

Server racks

cabinets are not unlike a server rack in that it contains and organizes IT

equipment. The main distinction between the two is that the server cabinet is

securely enclosed. Implying it has doors at the front and rear of the rack;

these doors are generally perforated in order to increase air circulation

within the enclosure. A server rack cabinet offers additional security due to

the locking component, restricting any kind of tampering. A rack is used to hold and organize IT equipment

in a system that is best for the optimization of the equipment and optimal

utilization of floor space. Generally a “U” space (usually called a Rack Unit

or RU) is a unit of measure and IT jargon for IT equipment. One single U space

amounts to 1.75 inches. Spacing of holes for a standard 19” rack is made in

groups of three holes, these three-hole groups are defined as a 1 U space. Now

a server is a device designed categorically to process requests from other

programs and equipment and deliver that data through the internet or local area

network. Servers execute several different functions including making various

computations for clients or data sharing. In its most crude definition, a

server is a high powered, high functioning, piece of machinery that pushes and

pulls data between the clients and itself.

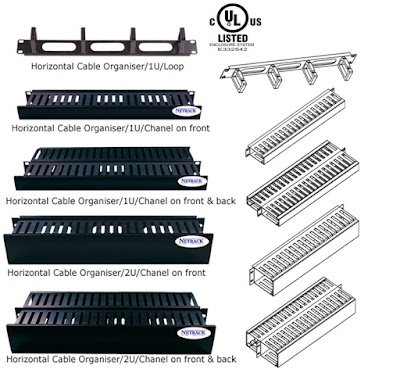

Data centres these

days consist of rows upon rows of server racks and network cabinets to support

a humongous load of data cables, network devices and power cords. To provide

proficient cable management within confined and tightly-spaced server racks is

quite challenging. But, cable management is no longer a challenge if you stick

to some basics and work with some tried and tested tools.

Within today’s fibre global

environment, multiple service providers demand greater bandwidth for their

subscribers. The technical people require consistent evolution that makes it

easier and more cost-effective for them to build critical fibre connections to deliver gigabit access speeds. The

best way engineers can accomplish this is to deploy fibre distribution units. This is an

enclosure that affords connectivity

between fibre optic cables and passive optical splitters in the

outside plant section of the network. It makes it quick and easy for reconfigurations

and service connections and, serves as a testing point for the outside plant

network. When cabinets are built with factory pre-connected feeder and distribution cable stubs, it ensures quick,

easy and dependable field installation. Fibre distribution hubs differ

in size and shape depending on the position in the network and the quantum of

customers needing service. The best technology afforded in the early years

of fibre-to-the-home constrained

manufacturers to large cumbersome metal cabinets. Placing a cabinet on

the ground, in a utility area met with no objection from either the carrier or

the users. Placing these cabinets on specially designed concrete pads or

utility mount poles was a common practice. Reality today is very different. Today,

FDHs are definitely space and cost effective. The markets demand mighty

subscriber numbers, a tinier footprint and a solution for permit restrictions

on above ground of utility equipment. Fibre distribution units are made in

different forms and sizes, and shapes, depending on their placement in the

network. There are outdoor and indoor FDHs. In the outdoor environment, there

are several choices depending on application and quantum of users requiring

service. Often times more than one design will meet the users requirements, so

it important to work with a trusted advisor to determine which is best for your

specific application. Fibre

distribution hubs enable the connection between fibre optic cables and passive

optical splitters in the outside plant segment of the network. A good FDH

provides high-density fibre connectivity to a weatherproof, compact, enclosure

to meet increasingly restrictive permitting ordinances.

Comments

Post a Comment