Promote a clean, safe and serene environment to your employees with data center rack management

Cable management and heat dissipation are some of

the major concerns of the data centers. The servers are the main unit that

drives the internal working and management of the IT sector for data

management, internet sharing, security, and memory. Therefore, these server

units work continuously and effectively to give uninterrupted service to the

client systems. This leads to the dissipation of heat and noise that create a

nuisance to the surrounding area.

These kinds of adverse issues produced by servers

may decrease the productivity level of the employees. In order to overcome

these issues, data center rack management is adapted to control the heat

dissipation and noise level so as to produce a safe and healthy environment for

the employees. Netrack, a leading company in the manufacturing of the

networking rack for servers and datacenters provides good quality data center racks

that would aid in providing a good cooling solution to the data centers.

Datacenter racks – The benefits

The data center racks provided by Netrack are

designed to protect the surrounding area from heat transfer and noise and also

is used to manage the stranded cables. It is a well-known fact that the server

room consumes a lot of power in the process. This leads to the consumption of a

lot of power and thereby increases the energy consumption cost. These racks are

a boon to the data centers as they completely reduce the amount spent on energy

consumption.

The data center racks are eco-friendly products as

they effectively utilize the available resource without causing an adverse

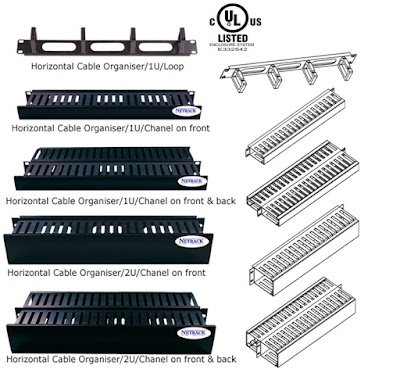

effect on the environment. The data center racks also manage well the cables

that run from server to the power sources or any other place.

Data

center racks – Effective heat management

The data center racks also avoid the mixing of hot

and cold air and maintain a stable temperature thereby preventing any short

circuits. This mixing is prevented by providing doors at both ends of the cold

aisle. The racks are also provided with blanking panels, plinth and rack side

thermal sealing so that the only way left for the cold air is through the

equipment.

Comments

Post a Comment